Products

DEPOSITION TOOLSPlasma Enhanced Chemical Vapour Deposition (PECVD)Inductively Coupled Plasma Chemical Vapour Deposition (ICPCVD)Atomic Layer Deposition (ALD)Ion Beam Deposition (IBD)ETCH TOOLSInductively Coupled Plasma Etching (ICP RIE)Reactive Ion Etching (RIE)Deep Silicon Etching (DSiE)Atomic Layer Etching (ALE)Ion Beam Etching (IBE)

Learning

![Phase diagram of the Ni—Mo system [2] with phases shaded and diffusion temperature indicated.](https://www.oxinst.com/learning/uploads/inline-images/ni-an23-fig1-750-20250530095359.png) Figure 1. Phase diagram of the Ni—Mo system [2] with phases shaded and diffusion temperature indicated.

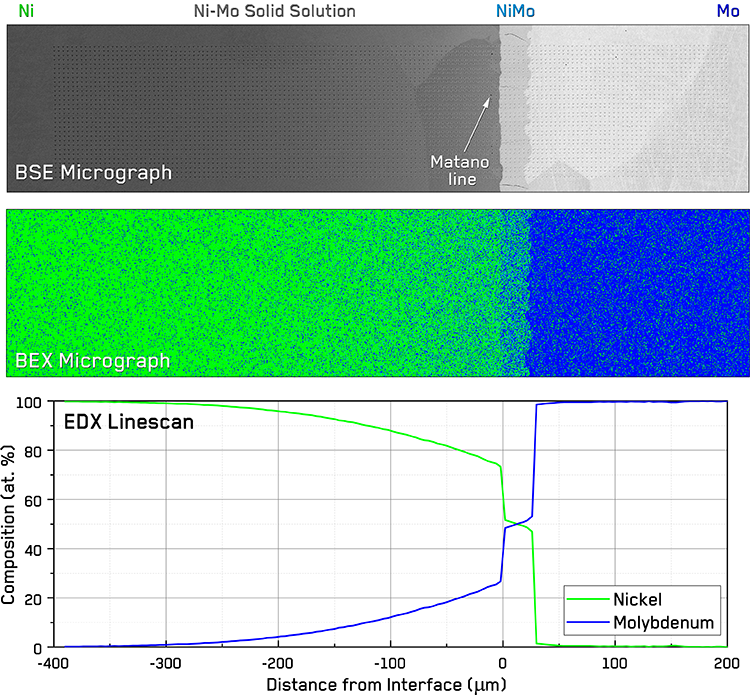

Figure 1. Phase diagram of the Ni—Mo system [2] with phases shaded and diffusion temperature indicated. Figure 2. Characterization of the Ni-Mo diffusion couple over the region where the 300° C map was performed.

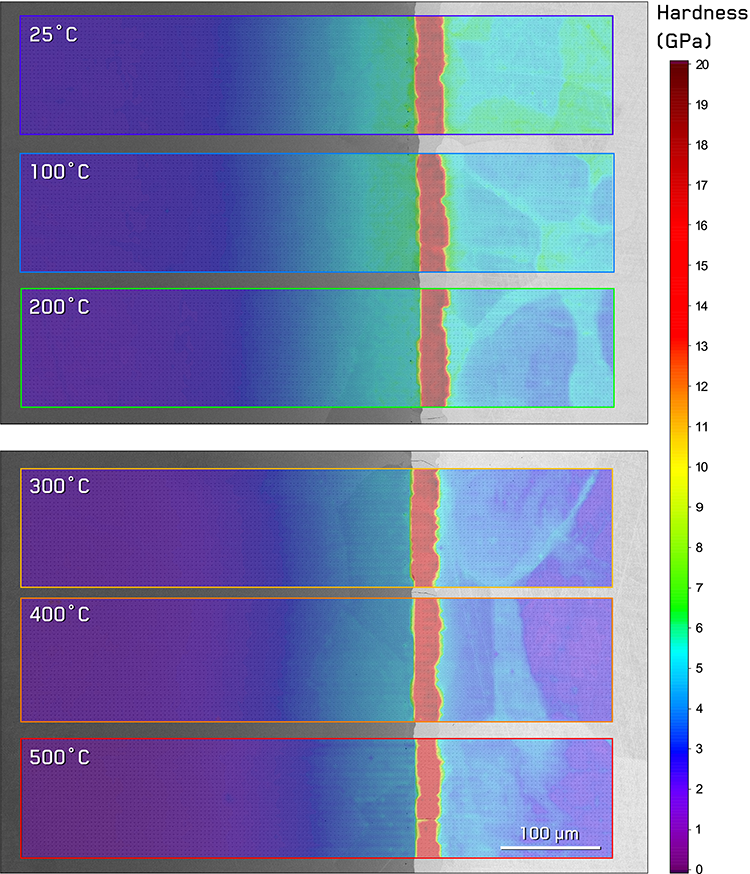

Figure 2. Characterization of the Ni-Mo diffusion couple over the region where the 300° C map was performed. Figure 3. Hardness maps overlaid on back-scattered electron micrographs of adjacent regions of the Ni—Mo diffusion junction acquired at temperatures from 25 to 500 °C.

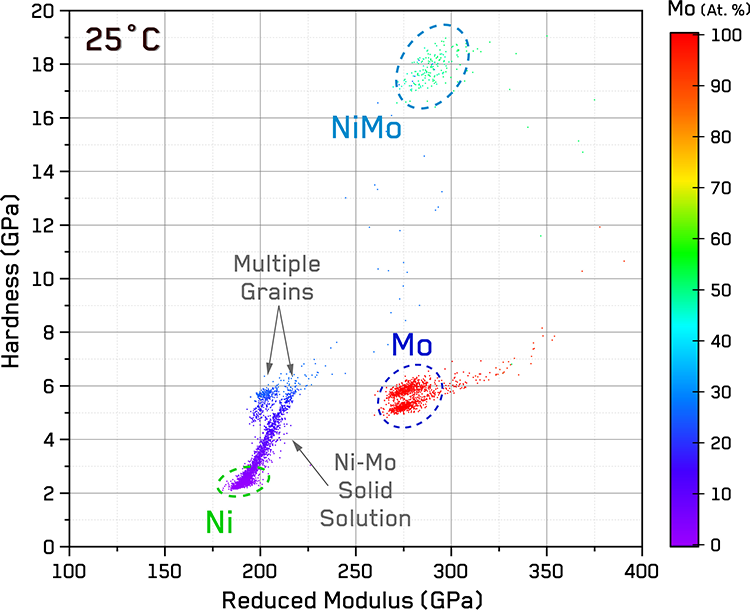

Figure 3. Hardness maps overlaid on back-scattered electron micrographs of adjacent regions of the Ni—Mo diffusion junction acquired at temperatures from 25 to 500 °C. Figure 4. 2D scatter plot showing hardness as a function of reduced modulus from room temperature mechanical microscopy results with datapoints color-coded using correlated EDX to illustrate compositional gradients and primary phases.

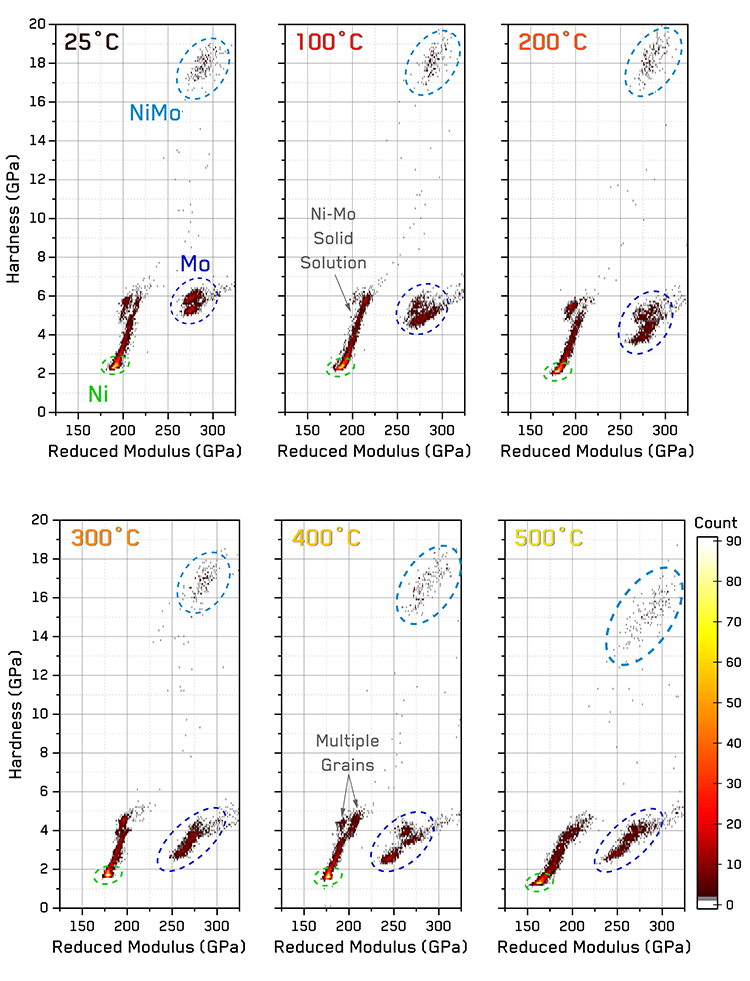

Figure 4. 2D scatter plot showing hardness as a function of reduced modulus from room temperature mechanical microscopy results with datapoints color-coded using correlated EDX to illustrate compositional gradients and primary phases. Figure 5. 2D histograms from operando mechanical microscopy measurements as a function of increasing temperature up to 500 °C with phases and features of interest labeled. Sample numbers and counts per 2D bin are consistent for each temperature for comparison.

Figure 5. 2D histograms from operando mechanical microscopy measurements as a function of increasing temperature up to 500 °C with phases and features of interest labeled. Sample numbers and counts per 2D bin are consistent for each temperature for comparison.![Hardness and reduced modulus of the primary phases in the Ni—Mo diffusion couple compared to literature values [6-8].](https://www.oxinst.com/learning/uploads/inline-images/ni-an23-fig6-750-20250530095908.png) Figure 6. Hardness and reduced modulus of the primary phases in the Ni—Mo diffusion couple compared to literature values [6-8].

Figure 6. Hardness and reduced modulus of the primary phases in the Ni—Mo diffusion couple compared to literature values [6-8].