Products

DEPOSITION TOOLSPlasma Enhanced Chemical Vapour Deposition (PECVD)Inductively Coupled Plasma Chemical Vapour Deposition (ICPCVD)Atomic Layer Deposition (ALD)Ion Beam Deposition (IBD)ETCH TOOLSInductively Coupled Plasma Etching (ICP RIE)Reactive Ion Etching (RIE)Deep Silicon Etching (DSiE)Atomic Layer Etching (ALE)Ion Beam Etching (IBE)

Learning

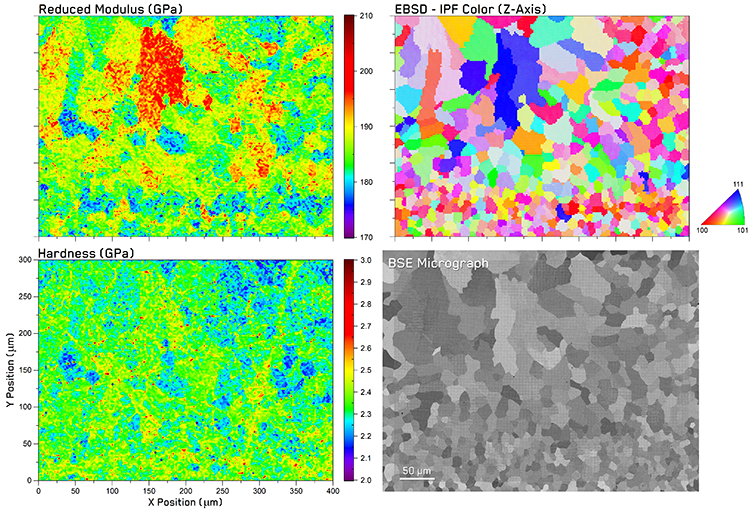

Figure 1. Mechanical microscopy results from suction-cast, pure Nickel with correlated indentation property maps with EBSD orientation and backscattered electron micrographs of the same region.

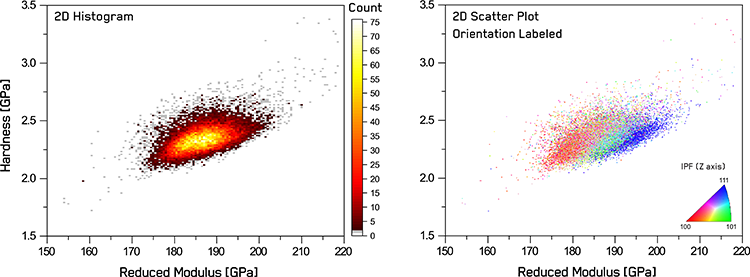

Figure 1. Mechanical microscopy results from suction-cast, pure Nickel with correlated indentation property maps with EBSD orientation and backscattered electron micrographs of the same region. Figure 2. Statistics of correlated mechanical property distributions: 2D histogram of hardness vs reduced modulus and 2D scatter plot with datapoints color coded using correlated EBSD data.

Figure 2. Statistics of correlated mechanical property distributions: 2D histogram of hardness vs reduced modulus and 2D scatter plot with datapoints color coded using correlated EBSD data.

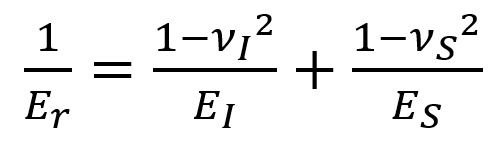

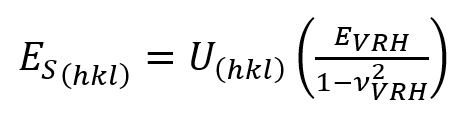

where EVHR and νVRH are the Voigt-Reuss-Hill (VRH) average values [8] and the correction factor U is given by

where EVHR and νVRH are the Voigt-Reuss-Hill (VRH) average values [8] and the correction factor U is given by![Orientation-dependence of hardness and reduced modulus of pure Nickel as a function of declination angle with datapoint color-coded using correlated EBSD data, along with reduced modulus trends derived from the literature [10-12].](https://www.oxinst.com/learning/uploads/inline-images/ni-an21-fig3-750-20250528123603.png) Figure 3. Orientation-dependence of hardness and reduced modulus of pure Nickel as a function of declination angle with datapoint color-coded using correlated EBSD data, along with reduced modulus trends derived from the literature [10-12].

Figure 3. Orientation-dependence of hardness and reduced modulus of pure Nickel as a function of declination angle with datapoint color-coded using correlated EBSD data, along with reduced modulus trends derived from the literature [10-12].