Products

DEPOSITION TOOLSPlasma Enhanced Chemical Vapour Deposition (PECVD)Inductively Coupled Plasma Chemical Vapour Deposition (ICPCVD)Atomic Layer Deposition (ALD)Ion Beam Deposition (IBD)ETCH TOOLSInductively Coupled Plasma Etching (ICP RIE)Reactive Ion Etching (RIE)Deep Silicon Etching (DSiE)Atomic Layer Etching (ALE)Ion Beam Etching (IBE)

Learning

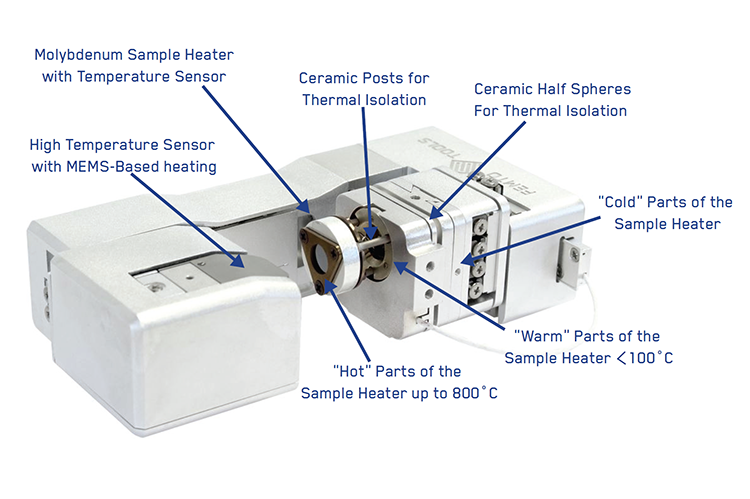

Figure 1. NMT04 with high temperature module features labeled. Cooling copper braids not shown.

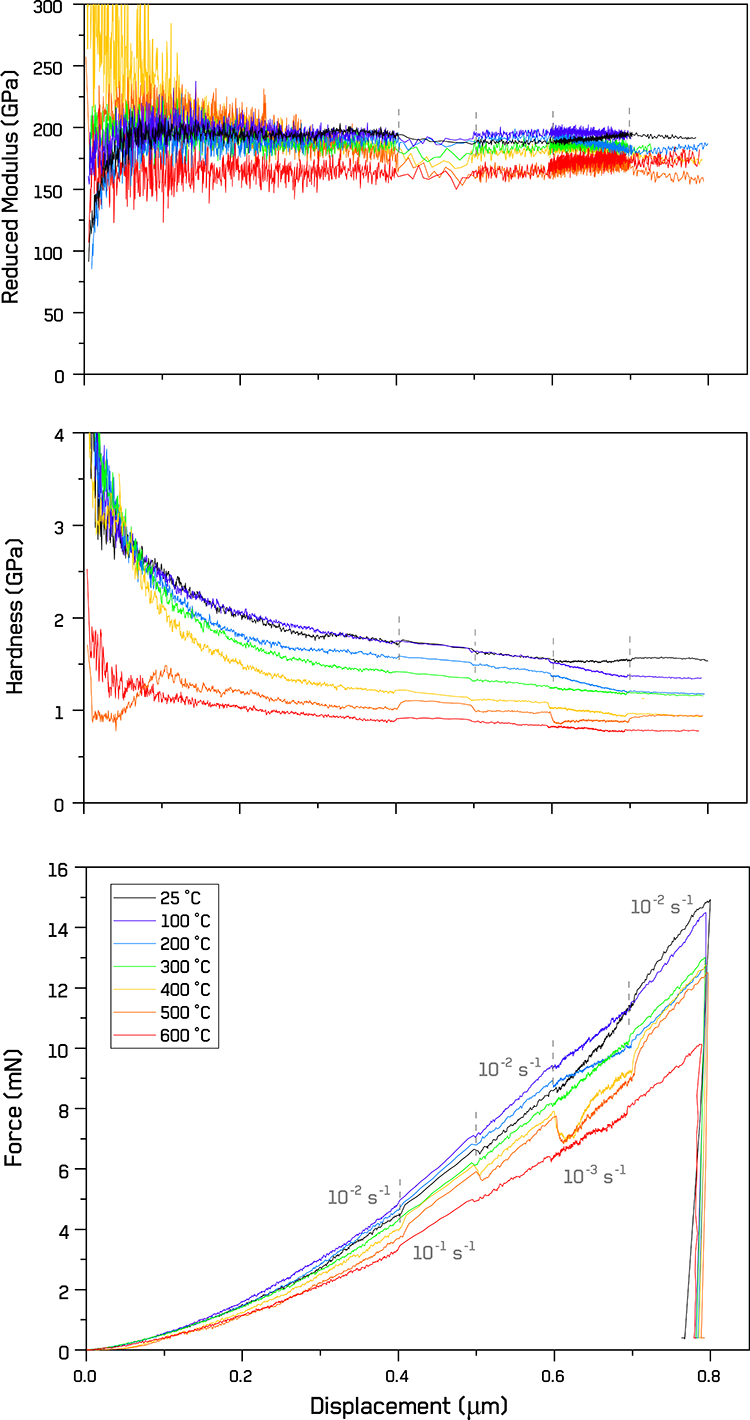

Figure 1. NMT04 with high temperature module features labeled. Cooling copper braids not shown. Figure 2. Force, hardness, and reduced modulus vs displacement during strain rate jump nanoindentation of Nickel at temperatures up to 600 °C.

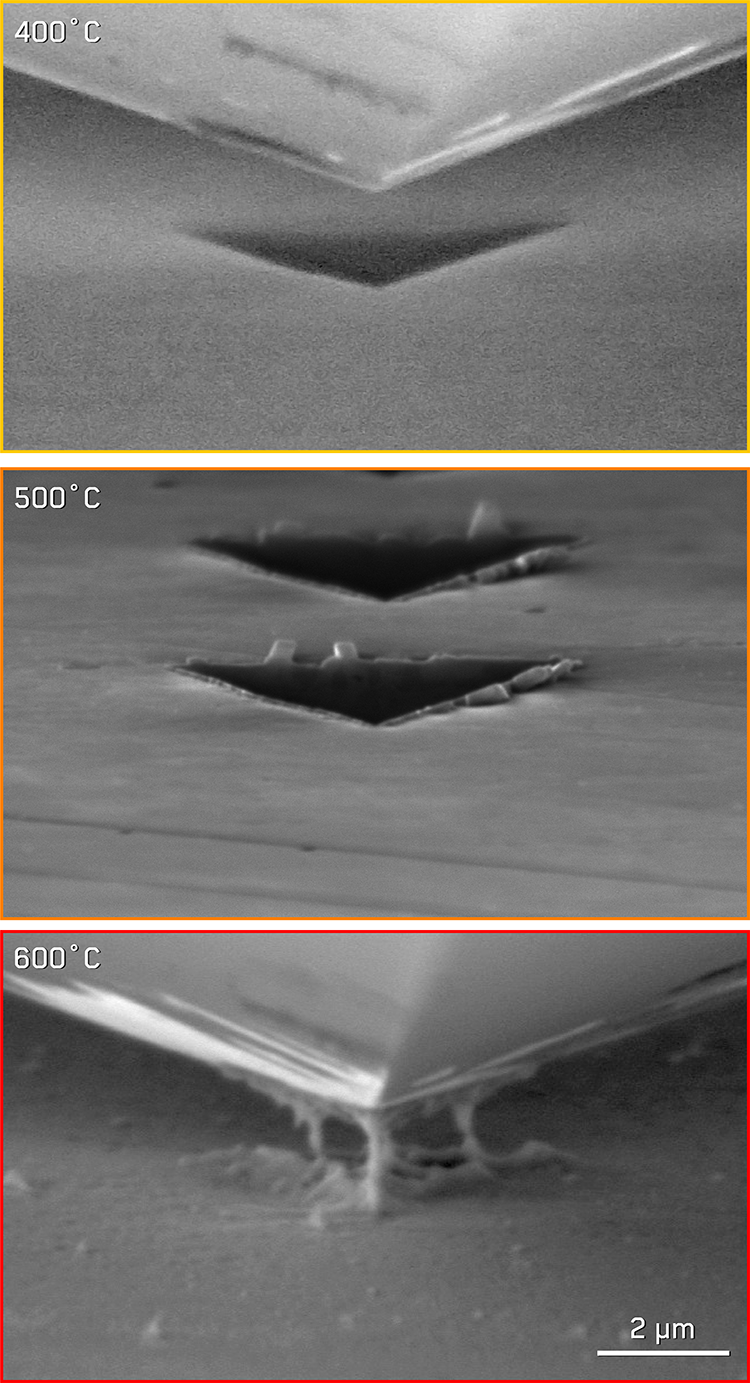

Figure 2. Force, hardness, and reduced modulus vs displacement during strain rate jump nanoindentation of Nickel at temperatures up to 600 °C. Figure 3. In-situ secondary electron micrographs captured during indentation at high temperatures illustrating the changes in mechanical behavior.

Figure 3. In-situ secondary electron micrographs captured during indentation at high temperatures illustrating the changes in mechanical behavior.![Hardness, reduced modulus, and strain rate sensitivity values for Nickel compared to literature values [7, 8] with top-view secondary electron micrographs of residual indents from each temperature.](https://www.oxinst.com/learning/uploads/inline-images/ni-an22-fig4-750-20250528133649.png) Figure 4. Hardness, reduced modulus, and strain rate sensitivity values for Nickel compared to literature values [7, 8] with top-view secondary electron micrographs of residual indents from each temperature.

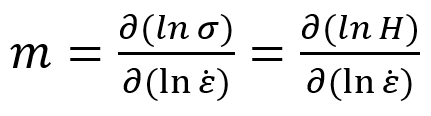

Figure 4. Hardness, reduced modulus, and strain rate sensitivity values for Nickel compared to literature values [7, 8] with top-view secondary electron micrographs of residual indents from each temperature. Hardness is related to strength using the Tabor confinement parameter, the Berkovich hardness value is related to the equivalent flow stress, σf, at 7% representative strain (eBerkovich = 7%) by the relationship, σf = H/2.8 [5]. This makes the strain rate sensitivity exponent, m, the slope of the trend on a log-log plot of stress and strain rate. The hardness values from the SRJ tests were taken after subtracting the influence of the ISE. Strain rate sensitivity trends broadly agree with those observed by Minnert et al. [7], with a slight increasing trend with temperature. SRS Values at lower temperatures near ambient are slightly higher then might be expected, this is attributed to a high defect density within the diffusion couple sample than a typical well-annealed polycrystalline sample. The increase in strain rate sensitivity at 500 °C is attributed to a diffusive process occurring during deformation, producing the extruded and recrystallized features seen in the micrographs. Values at 600 °C return to the trend observed by Minnert et al. However, without a residual impression, the deformation mechanism, though almost certainly including some form of diffusive process, remains unclear.

Hardness is related to strength using the Tabor confinement parameter, the Berkovich hardness value is related to the equivalent flow stress, σf, at 7% representative strain (eBerkovich = 7%) by the relationship, σf = H/2.8 [5]. This makes the strain rate sensitivity exponent, m, the slope of the trend on a log-log plot of stress and strain rate. The hardness values from the SRJ tests were taken after subtracting the influence of the ISE. Strain rate sensitivity trends broadly agree with those observed by Minnert et al. [7], with a slight increasing trend with temperature. SRS Values at lower temperatures near ambient are slightly higher then might be expected, this is attributed to a high defect density within the diffusion couple sample than a typical well-annealed polycrystalline sample. The increase in strain rate sensitivity at 500 °C is attributed to a diffusive process occurring during deformation, producing the extruded and recrystallized features seen in the micrographs. Values at 600 °C return to the trend observed by Minnert et al. However, without a residual impression, the deformation mechanism, though almost certainly including some form of diffusive process, remains unclear.