Products

DEPOSITION TOOLSPlasma Enhanced Chemical Vapour Deposition (PECVD)Inductively Coupled Plasma Chemical Vapour Deposition (ICPCVD)Atomic Layer Deposition (ALD)Ion Beam Deposition (IBD)ETCH TOOLSInductively Coupled Plasma Etching (ICP RIE)Reactive Ion Etching (RIE)Deep Silicon Etching (DSiE)Atomic Layer Etching (ALE)Ion Beam Etching (IBE)

Learning

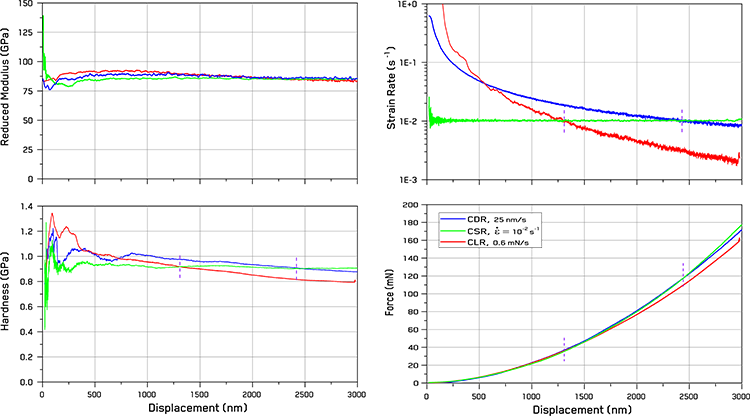

and using values for a diamond indenter (E = 1120 GPa and ν = 0.07) produces a reduced modulus value of Er = 70.24 GPa for the fused silica. These samples are used as standard references for indenter area function calibrations and as a test sample for this application note.

and using values for a diamond indenter (E = 1120 GPa and ν = 0.07) produces a reduced modulus value of Er = 70.24 GPa for the fused silica. These samples are used as standard references for indenter area function calibrations and as a test sample for this application note.

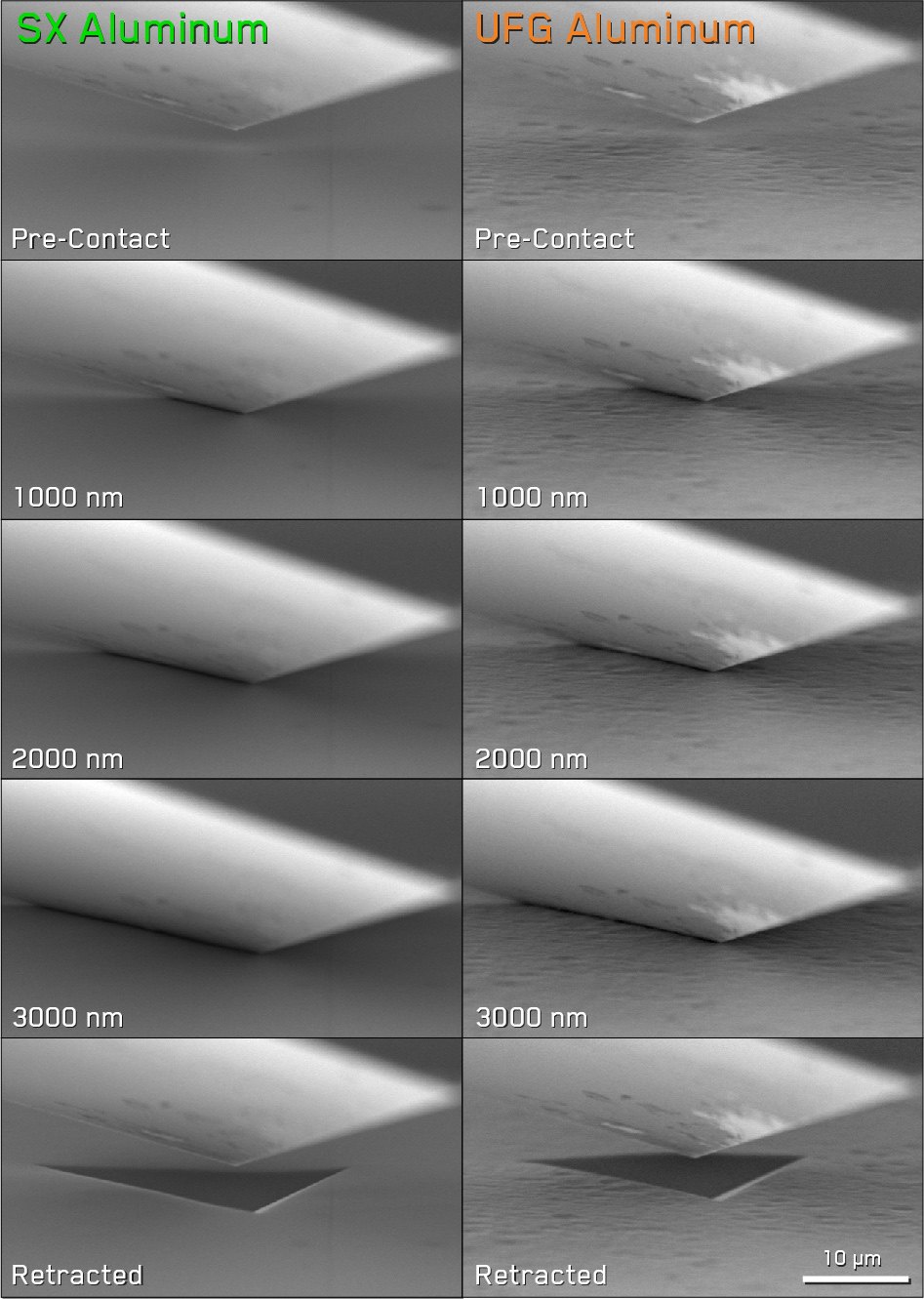

Figure 4. Secondary electron micrographs captured in-situ during indentation showing the progression of the deformation at different displacements.

Figure 4. Secondary electron micrographs captured in-situ during indentation showing the progression of the deformation at different displacements.

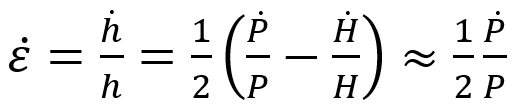

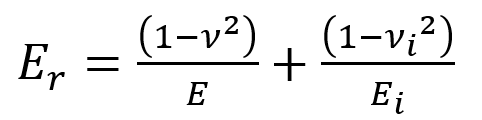

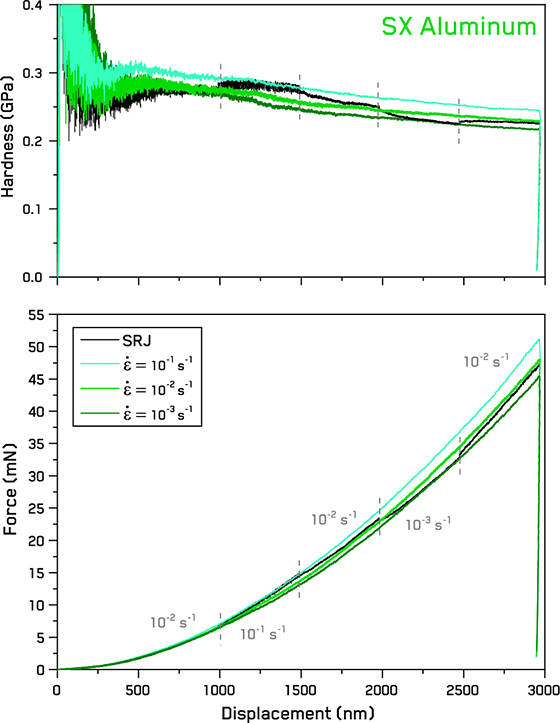

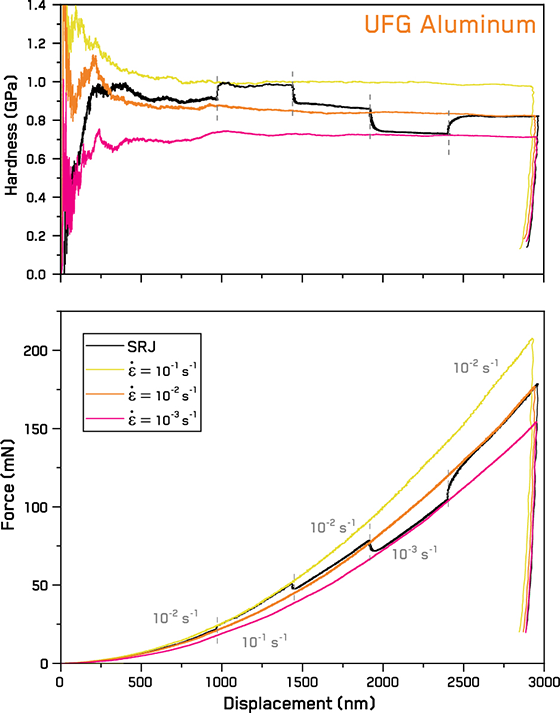

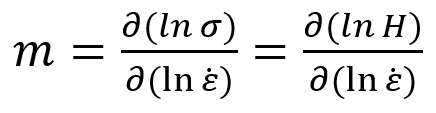

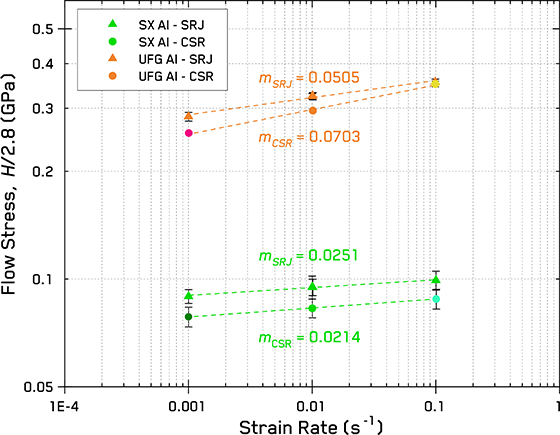

which results from the first equation. Using the Tabor confinement parameter, the Berkovich hardness value is related to the equivalent flow stress, σf, at 7% representative strain (eBerkovich = 7%) by the relationship, σf = H/2.8 [4]. This makes the strain rate sensitivity exponent, m, the slope of the trend on a log-log plot of stress and strain rate - Figure 6. The values shown in Figure 6 are taken from the final 10-20% of the hardness curves of the CSR indentations, and the hardness values from the SRJ tests were taken after subtracting the influence of the ISE. Values for fused silica are not plotted, but the measured strain rate sensitivity (m = 0.011) is consistent with previous measurements [9].

which results from the first equation. Using the Tabor confinement parameter, the Berkovich hardness value is related to the equivalent flow stress, σf, at 7% representative strain (eBerkovich = 7%) by the relationship, σf = H/2.8 [4]. This makes the strain rate sensitivity exponent, m, the slope of the trend on a log-log plot of stress and strain rate - Figure 6. The values shown in Figure 6 are taken from the final 10-20% of the hardness curves of the CSR indentations, and the hardness values from the SRJ tests were taken after subtracting the influence of the ISE. Values for fused silica are not plotted, but the measured strain rate sensitivity (m = 0.011) is consistent with previous measurements [9].

![Activation volume values from literature [8] compared with current values.](https://www.oxinst.com/learning/uploads/inline-images/ni-an6-fig7-560-20250526092136.png)