Oxford Instruments NanoAnalysis Scientific Paper Award Recognises Outstanding Publications

Researchers from China, New Zealand, India and the UK are honoured for their work with Oxford Instrument Detectors.

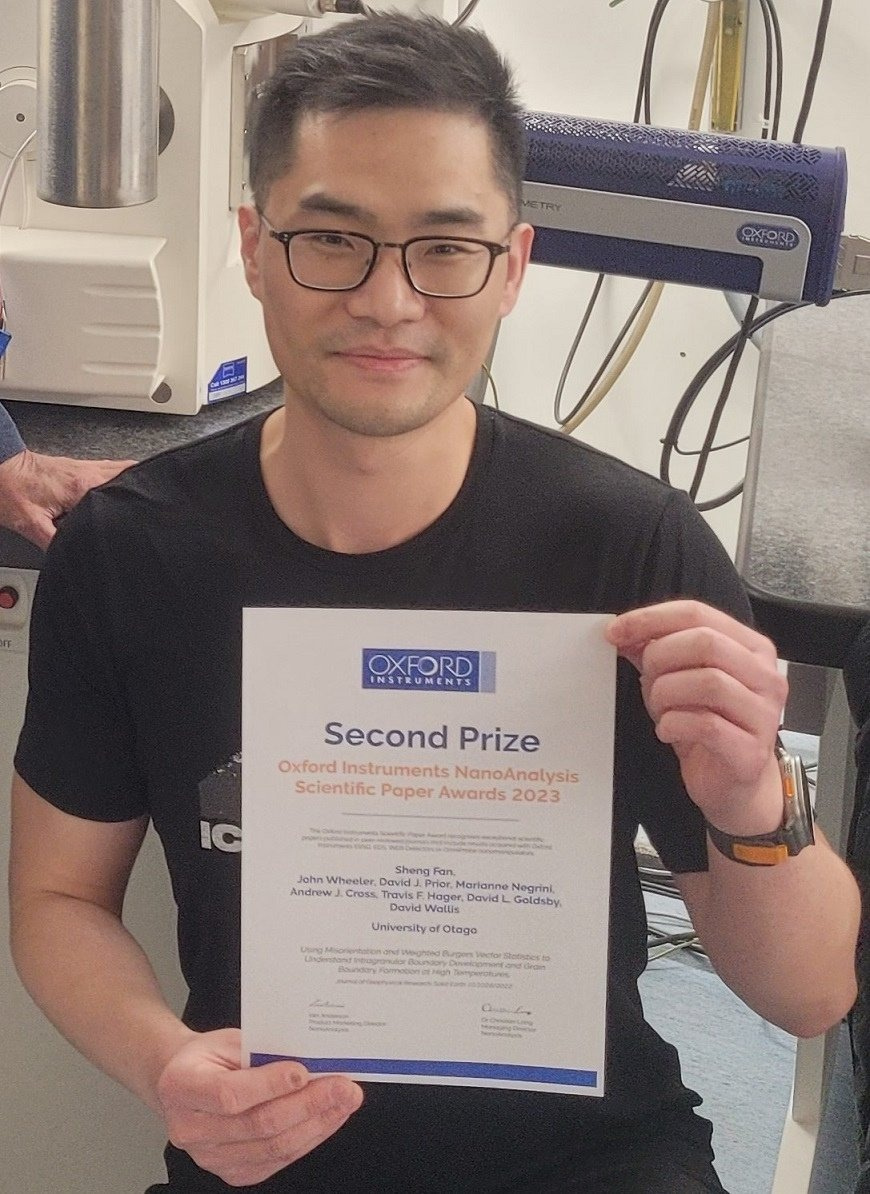

Left to right: First prize winner: Chi Jin from Northwestern Polytechnical University China and Zhenlei Li from Oxford Instruments China, Second prize winner: Sheng Fen from University Otago New Zealand, Third prize winner: Arindam Sarkar, Abhijeet Suryawanshi, Santu Biswas & Manish A. Mamtani from the Indian Institute of Technology (IIT) Kharagpur India

The Oxford Instruments NanoAnaylsis Scientific Paper Award 2023 has been presented to scientists from China, New Zealand, India and UK for their work. The award recognises the exceptional, cutting-edge research published in peer-reviewed journals in 2022 that included data and results acquired with Oxford Instruments EBSD, EDS, WDS Detectors or OmniProbe nanomanipulators.

- First Prize: Winner of $500 Amazon™ gift card, Chi Jin, Xiaolin Li, Haozhe Li, Qian Li, Haifeng Wang - Northwestern Polytechnical University China. Tribological performance of a TiZrNbMo refractory high entropy alloy at elevated temperatures. Journal of Alloys and Compounds 920 (2022) 165915

- Second Prize: Winner of $300 Amazon™ gift card, Sheng Fan, John Wheeler, David J. Prior, Marianne Negrini, Andrew J. Cross, Travis F. Hager, David L. Goldsby, David Wallis- University of Otago New Zealand. Using Misorientation and Weighted Burgers Vector Statistics to Understand Intragranular Boundary Development and Grain Boundary Formation at High Temperatures. Journal of Geophysical Research: Solid Earth 10.1029/2022JB024497

- Third Prize: Winner of $200 Amazon™ gift card, Arindam Sarkar, Abhijeet Suryawanshi, Santu Biswas & Manish A. Mamtani- Department of Geology & Geophysics, Indian Institute of Technology (IIT) Kharagpur India. Opposite Shear Sense from Quartz Shape and Crystallographic Preferred Orientation – a Dichotomy and Its Implications for Kinematic Analysis. Jour. Geol. Soc. India (2022) 98:1337-1342

- Highly Commended Prize: Jack Aspinall, David J. Armstrong & Mauro Pasta - University of Oxford UK. EBSD-coupled indentation: nanoscale mechanics of lithium metal. Materials Today Energy 30 (2022) 101183

“I was amazed at the range and quality of submissions for this our first year of the Oxford Instruments NanoAnalysis Scientific Paper Awards,” said Dr Matt Hiscock, Head of Product Science at Oxford Instruments and chief judge. "Our panel of expert judges found it very difficult to select the winners from such tough competition. I would like to recognise everyone who took time to submit a paper entry. This competition clearly highlights the cutting-edge work that is being carried out across a wide range of applications."

“We look forward to reading and judging the entries for next year's Oxford Instruments NanoAnalysis Scientific Paper Awards".

The Paper Award First Prize: Microstructure, oxidation resistance, tribological properties and mechanisms of RHEAs

Refractory high-entropy alloys (RHEAs) have attracted extensive attention in the field of high-temperature for their excellent high-temperature resistance, mechanical properties, and wear performance. One kind of RHEA, Ti-Zr-Nb-Mo, is a potential wear-resistant material due to its high strength and low modulus.

In this study, Chi Jin and his colleagues from Northwestern Polytechnical University China, Xiaolin Li, Haozhe Li, Qian Li and Haifeng Wang, studied the microstructure, oxidation resistance and tribological properties of TiZrNbMo0.6 RHEA.

SEM and EDS were used to characterise the morphology and composition of the wear surfaces and cross-sections, as well as the Si3N4 counterparts. The results indicate that the TiZrNbMo0.6 alloy has an optimal wear resistance, as it forms a compacted and continuous glaze layer on the surface at a temperature of 500 °C. The evolution of the wear mechanism at different temperatures has been discovered, and the oxidation test has been conducted to explain the mechanisms of tribological properties at high temperatures. The dominant wear mechanism changes from abrasive wear at room temperature to oxidative wear and slight abrasive wear at 500 °C. With the wear temperature increasing to 800 °C, the dominant wear mechanism is severe oxidative wear, followed by partly abrasive wear, which results in a higher wear rate at 800 °C than that at 500 °C.

The Paper Award Second Prize: Using Misorientation and Weighted Burgers Vector Statistics to Understand Intragranular Boundary Development and Grain Boundary Formation at High Temperatures

Under high stress and temperature, minerals develop internal boundaries, due to crystal defects, which evolve into grain boundaries thereby subdividing and weakening the minerals to facilitate large-scale flow. However, the precise physical mechanism driving this transformation remains unclear.

In this study, Sheng Fen and his colleagues at the University of Otago, New Zealand, address this question by integrating deformation experiments with advanced microscopy techniques (including EBSD) and offer new insights into the process of grain-boundary formation and transformation.

The Paper Award Third Prize: Opposite Shear Sense from Quartz Shape and Crystallographic Preferred Orientation – a Dichotomy and Its Implications for Kinematic Analysis.

In this study, Arindam Sarkar and his colleagues at the Indian Institute of Technology (IIT) Kharagpur bring to light a dichotomy that is noted in a naturally deformed rock, where the sense of shear inferred from quartz shape preferred orientation (SPO) is opposite to that deciphered from the crystallographic preferred orientation (CPO).

Microstructural and quartz CPO data (obtained through SEM-EBSD analysis) from a quartz vein hosted in sinistrally sheared mylonitised granite of Gadwal region (Dharwar Craton) are presented. The vein thin section is prepared parallel to the kinematic reference frame (XZ section of the strain ellipsoid) using field-based information which allows determination of sense of shear using microstructures. The dichotomy noted from Domain-II indicates that there maybe pitfalls in direct interpretation of kinematics based exclusively on quartz SPO analysis. Hence, caution must be exercised while extrapolating microscale kinematics based on quartz SPO to the regional scale.

The Oxford Instruments NanoAnalysis Paper Award 2024 will be open for submissions in February 2024

The Oxford Instrument jury looks forward to receiving many exceptional submissions for the Oxford Instruments NanoAnalysis Paper Award 2024. Articles are eligible if they were published in 2023 (in print or online) in a peer-reviewed journal and include results acquired with Oxford Instruments BEX EBSD, EDS, WDS Detectors or Omnirobe nanomanipulators.