20 March 2023

Qualification Programmes for Plasma Polish

Oxford Instruments Accelerating Qualification Programmes Ready for Plasma Polish Production Ramp in 2023

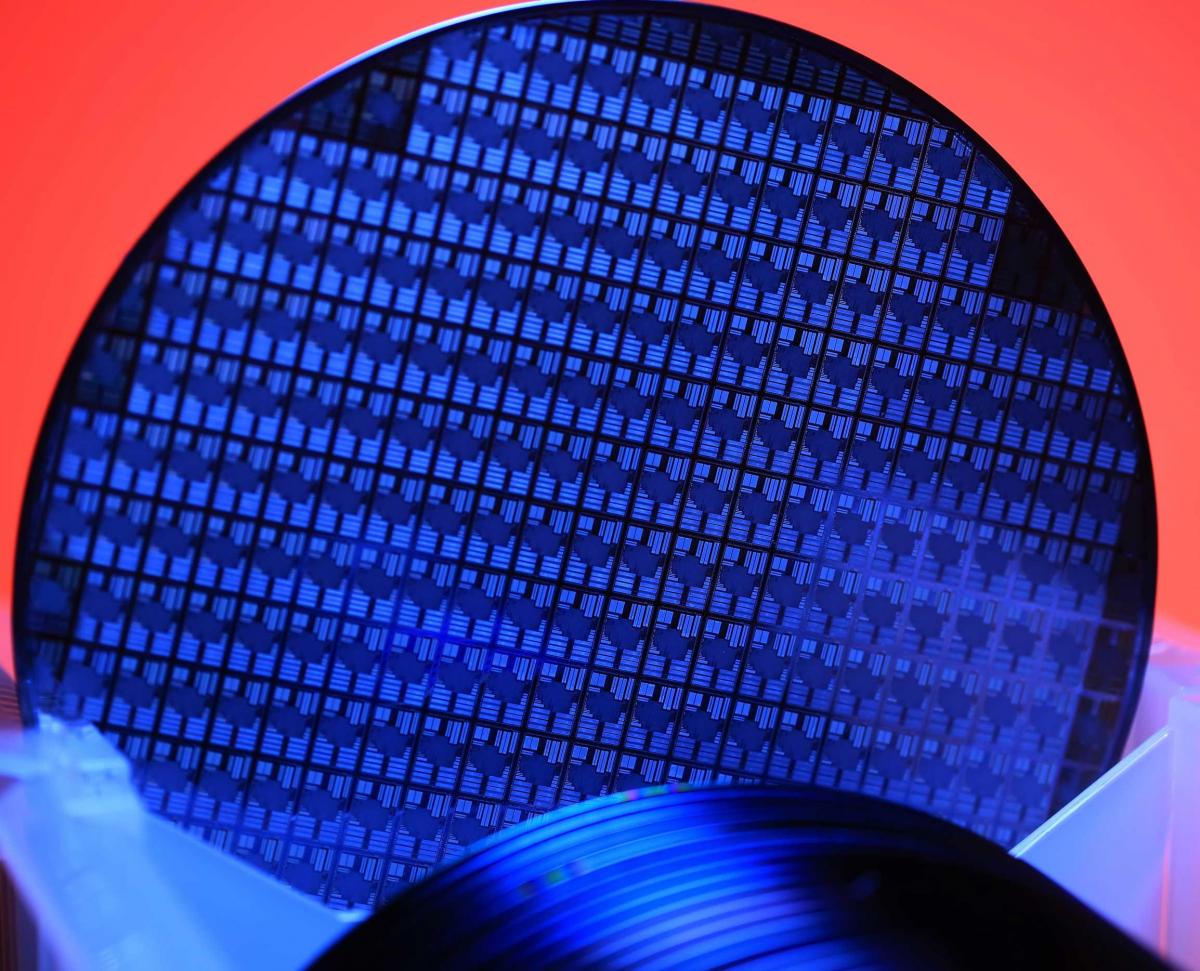

With intensive qualification projects underway with several leading manufacturers, it has been confirmed that Oxford Instruments’ Plasma Polish technique can be applied, with great effect, to improve silicon carbide (SiC) substrate surface and reduce subsurface damage for multiple production processes, where SiC crystal quality is a critical yield-limiting factor. The 200-mm-compatible SiC substrate polishing technique, launched by Oxford Instruments at the International Conference on Silicon Carbide and Related Materials, Davos, in September 2022, is being tested with commercial partners at several points in the SiC device fabrication supply chain, such as boule growth, pre and post-epi and in between epi layers, to meet higher voltage device requirements. In addition, the repeatability and damage-reducing benefits of Plasma Polish have also been demonstrated with 12 suppliers across the USA, EMEA and Asia, with the process therefore proving to be an effective solution on any given SiC material.

Solution in qualification with several leading SiC device and substrate manufacturers.

Qualification of the technique has demonstrated state-of-the-art surface and subsurface damage reduction capability, targeting maximum power device yield. In addition to technical advantages, Plasma Polish brings opportunities to reduce the polishing cost of SiC substrates across multiple steps in the supply chain, while at the same time reducing the environmental impact of the process. An alternative approach to Chemical Mechanical Polish (CMP), Plasma Polish lends itself to the production of high yield, cost-effective power devices – helping to address a key challenge to SiC adoption.

With significant market interest in Plasma Polish coming from key customers throughout the SiC supply chain, Oxford Instruments is at advanced stages of qualification with multiple companies and is ramping up Plasma Polish module production. Bas Derksema, Oxford Instruments Plasma Technology Global Sales and Marketing Director, comments:

“The engagement we have had with customers so far has been phenomenal, and we are continuously confirming the benefits Plasma Polish offers to solve current and future technical challenges hampering SiC adoption. Both gallium nitride and silicon carbide are key to Oxford Instruments’ growth plans in the wide band gap power space, and we have production solutions and a very exciting leading-edge development pathway aligned to our customers’ current and future challenges.”

“Our new Severn Beach production and research facility, coming online in the next twelve months, increases our production capacity by over 50%, with a doubling of application lab space, which will allow us to continue developing market-leading innovative solutions, and ramp up our production capacity to respond to growing market demand.”

Oxford Instruments is attending APEC 2023 in Orlando, Florida, the major annual Applied Power Electronics Conference for practical and applied power electronics. The team will be on hand to discuss how Oxford Instruments’ SiC and GaN substrate prep, surface modification, feature etch, ALE, ALD and Etchpoint™ process solutions can generate more high-quality wafers per day at lower cost.

- Ends -

Issued for and on behalf of Oxford Instruments Plasma Technology