It’s been a crazy few months at Oxford Instruments. We have introduced many new products over the years, some of them very innovative and very revolutionary. However, we have not introduced a new product which enables a new technique before and that’s been very exciting. Judging by the reaction, many people are hearing about it and want to understand more about it all.

Perhaps not surprisingly there is one area that is behind so many questions I am asked: How is BEX imaging different from EDS mapping?

Afterall the Unity detector has X-ray sensors, so surely, it’s an EDS detector for EDS mapping, and we are showing data that looks at least superficially like that you would see from an EDS map acquisition. However, it also has electron sensors like a BSD (backscatter detector) and produces images that look awfully like backscatter images, therefore it’s an imaging detector perhaps? What’s going on here? What is BEX imaging and how does Unity achieve BEX imaging?

BEX Imaging vs X-ray Mapping

BEX imaging is all about the seamless and simultaneous integration of signals into a single imaging experience to understand a sample as quickly and in as much detail as possible. The signals of most importance in this case are electrons for topography and materials contrast and X-ray for constituent elements. This means in essence real-time imaging at a wide range of working distances, and imaging conditions.

In contrast when X-ray mapping in a SEM, where only X-rays are collected, the map information builds more gradually, under conditions optimised to ensure accuracy and throughput from a conventional EDS detector. Therefore, a prescribed working distance and elevated beam current is needed.

This highlights a different requirement of BEX imaging which makes a conventional EDS detector unsuitable to be the main provider of its X-ray information. That is simply geometry of X-ray detection, which must offer high signal for rapid image collection at beam conditions typical of SEM imaging. Therefore, we have developed a radically different type of detector that collects far more X-rays and is much less sensitive to sample height than a conventional side mounted EDS detector.

Conventional EDS detectors however, still have an important contribution to BEX imaging as we shall see.

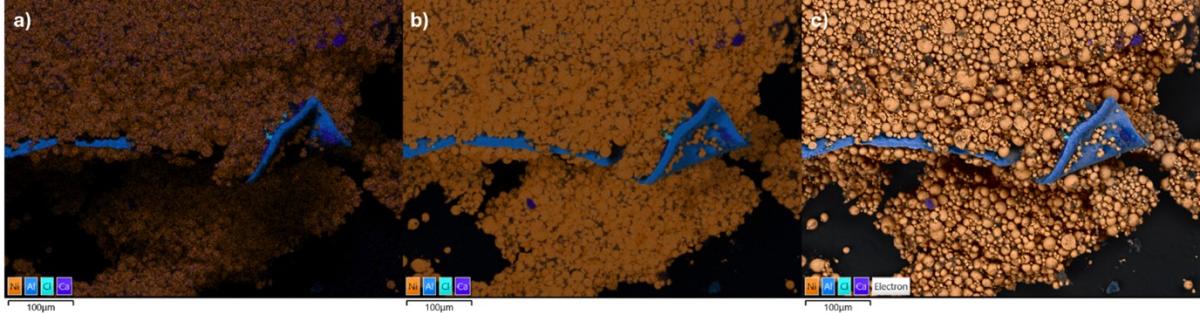

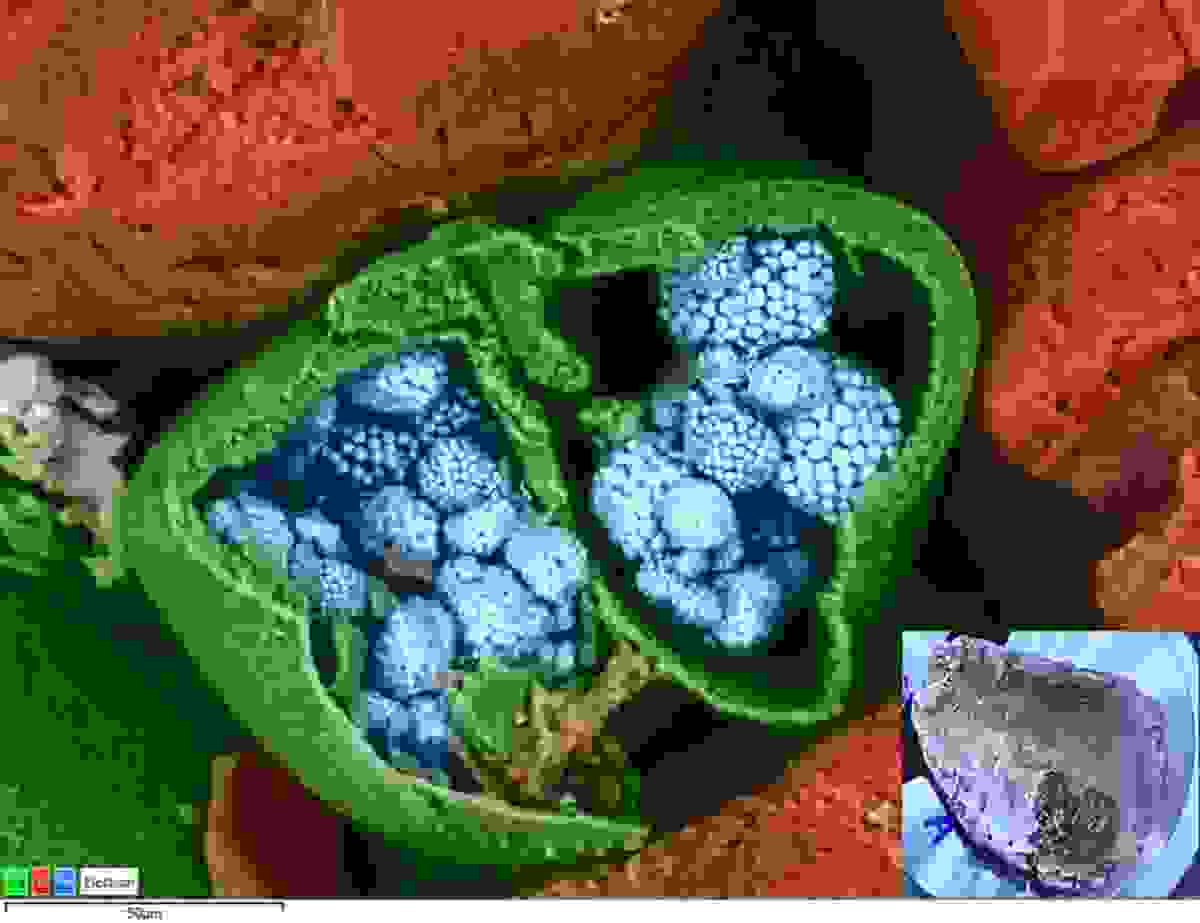

Comparing the output from EDS and BEX when imaging a battery cathode sample. A) EDS maps B) BEX element images from the X-ray detectors in the Unity detector, note the significantly higher intensity and data from the shadowed parts of the sample in A), C) Complete BEX image where X-ray and backscatter images from Unity are combined.

How has Unity been designed to provide BEX imaging?

That brings us onto our new Unity detector, which headlines as the world's first BEX (backscatter electron and X-ray) detector. It is a detector designed to enable BEX imaging to be a practical technique by putting electron and X-ray sensors in one unit between the pole-piece and the sample. It therefore occupies the traditional back-scatter detector (BSD) position in the microscope, giving X-ray detectors the advantage of this geometry and fulfilling the need to provide a much higher signal (due to the small distance to the sample) and a geometry that always has good line of sight at any sample height. A very nice additional benefit of this position, in comparison to EDS, is the overhead view which is much less sensitive to topography and therefore also largely removes the problem of shadowing for rough/highly topographic samples.

I have had many questions about this design approach, particularly in comparison to EDS. For example, one question is about element range, which for Unity means detection of elements with atomic number greater or equal to sodium, thus no light element detection.

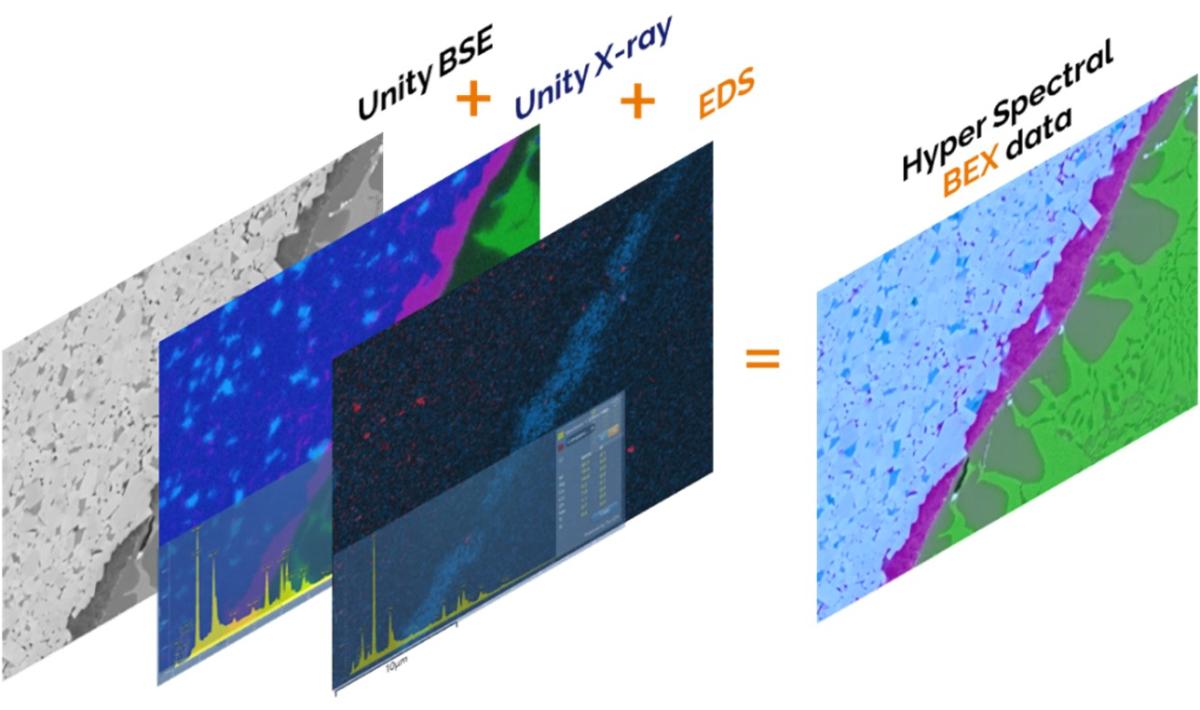

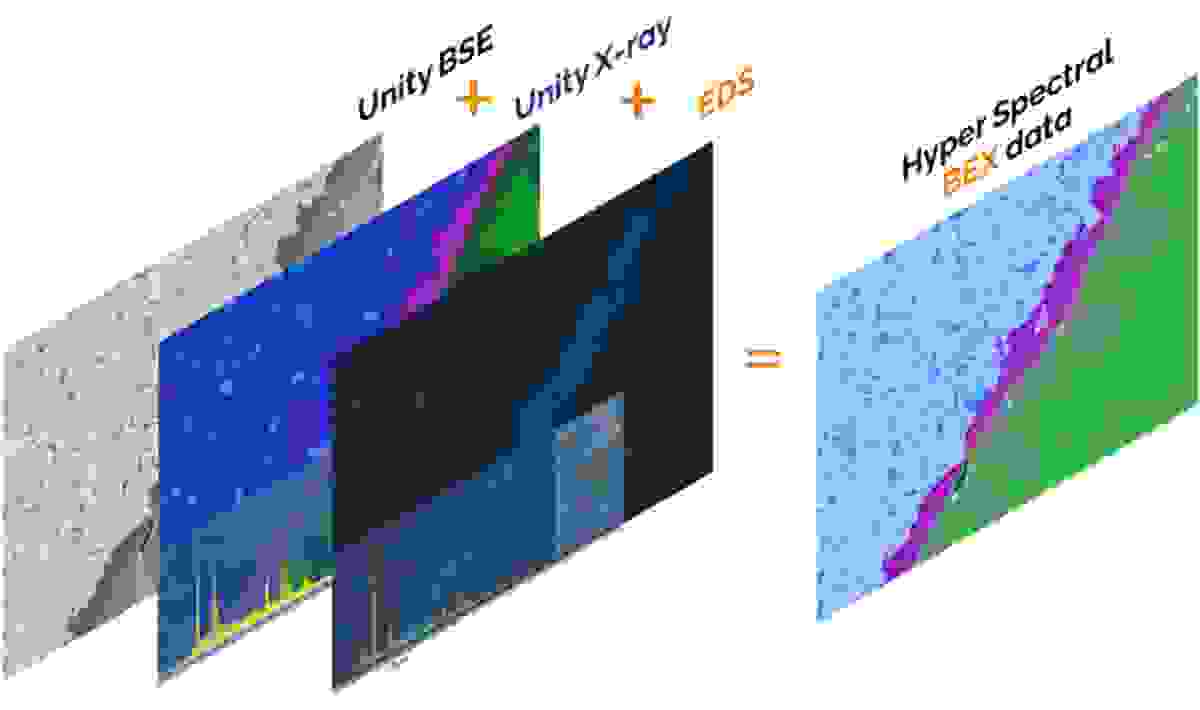

This design choice is advantageous for Unity and EDS allows us to optimise their contribution to BEX imaging. For Unity the signal processing is optimised for higher energy, faster to process signals, meaning we can process more X-rays faster and more accurately. So, for example, pile-up, a feature of high-count rate EDS mapping, is much less of an issue. The special shape of Unity sensor head allows line of sight of an EDS detector at most working distances. Under BEX imaging conditions the count rate of the EDS is much lower and is ideal for more analytical tasks like automatic peak identification and low energy X-ray measurement. Therefore, by combining Unity with a conventional EDS detector, we actually have the best of all worlds: accurate element ID to identify the elements of interest in a sample and optimised light element detection (from EDS), and very fast low artefact X-ray imaging for the majority of elements (from Unity). As EDS data is also collected, we have the quantitative information collected at the same time, and it is automatically combined into a single hyper-spectral image with the data collected from all other sensors. The design of the AZtec BEX imaging software is such that this is handled in the background seamlessly and the data shown for different data types (e.g. spectrum or image) or elements is selected automatically so the right and best data is presented to the user. In this way EDS also follows the BEX philosophy and is simply used as another available signal source that adds more information to the BEX image. BEX in reality is normally Backscatter, X-ray, Secondary (from the SE detector) and EDS all collected together.

All BEX imaging is a multi-signal dataset combined together to produce a detailed picture of the sample.

In praise of BEX imaging in low vacuum mode

Once you gain an acceptance that BEX is not EDS, and is not constrained in the same way, and it doesn’t need to be ‘analytical’ in the same way, you are liberated to use BEX imaging under conditions where doing EDS is problematical or troublesome. Take for example low vacuum mode. I’ve never been a great user of EDS in LV mode due to the artefacts caused by scattering of the beam and low count rates. However, as soon as you stop being concerned with the analytical expectations of EDS and are seeking imaging to understand the structure and make-up of a sample, then LV mode acquisition is attractive, especially for rough, uncoated specimens. During a recent visit to Japan, I realised instead of spending less than 1% of my time in LV mode, more like 40% of my SEM time had been using LV mode with BEX imaging. The electron sensors in Unity also work very well in LV mode, and at 50-100 Pa it is easy to collect live, clear, high quality, BEX images including electron and X-ray information. It’s easy to forget it’s LV mode.

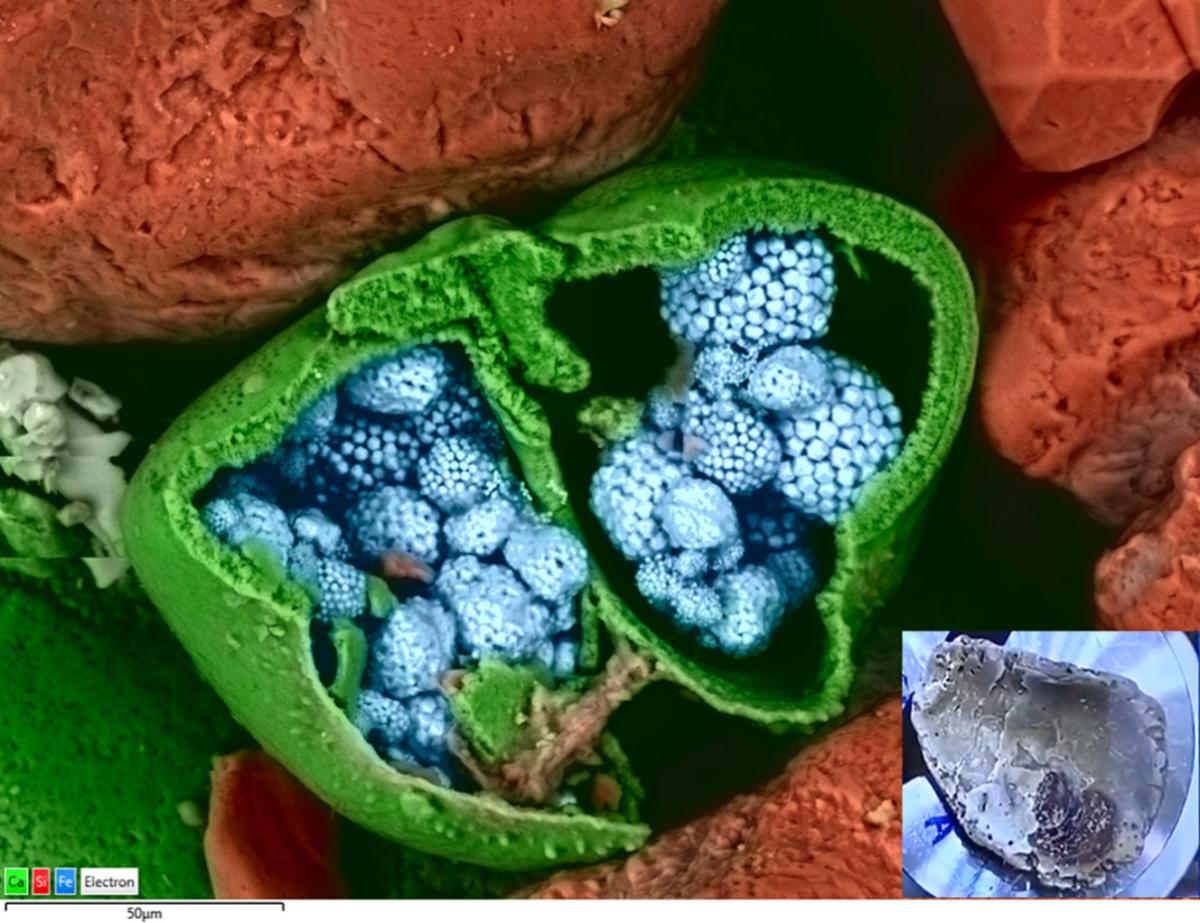

BEX image of an uncoated shell collected in VP mode, note the image quality and the level of elemental information that is revealed from this highly topographic area.

Can Unity do X-ray mapping?

One other obvious question is what about traditional X-ray mapping: does it still have a role, and can Unity be used for it? The answer to that is yes, and yes. X-ray mapping certainly still has a big role to play in the SEM. X-ray mapping with EDS detectors under conditions dedicated for accurate analysis remains the solution for high quality elemental and quantitative analysis, where the collection of the data is optimised for determining accurately the compositional differences of the elements in different phases. Unity is fully compatible with the X-ray mapping software in AZtec and can be used in combination with a conventional EDS detector during X-ray map acquisition, with the capability to compare the X-ray maps collected with each detector. X-ray mapping is also much more efficient when BEX imaging has been used to identify those regions of the sample that require more detailed analysis by a more detailed and accurate EDS approach.

Ask yourself the question, how much time do you spend on a SEM doing all the exploratory work before collecting the data you actually analyse or report? If the answer is a significant proportion of the time, then you will find Unity and the BEX technique liberating. A SEM without BEX, is like driving a car without GPS, or watching a film in black and white: you can do/enjoy it but it's either not quick or easy as it should be or it’s missing some critical details, to achieve a satisfactory outcome or experience.

If you would like to learn more about BEX, you can watch our webinar on demand here.