As I neared the completion of my PhD, I took the opportunity to attend an exciting workshop hosted by Oxford Instruments at Goldschmidt 2023. Little did I know, this event would introduce me to a pioneering new technique – backscattered electron and X-ray (BEX) - right on the heels of the Unity detector launch. Looking back, I can't help but reflect on how this innovation could have streamlined my data collection process, potentially saving me precious time and resources.

In today's post, I'm taking a retrospective dive into the missed opportunities, when implementing the BEX technique could have yielded significant advantages during my research journey. My hope is that by sharing these insights, fellow researchers can harness the power of BEX and Unity to acquire more data, faster and at lower cost.

In the Before - Times

Throughout my PhD studies, I delved into the intricate realm of unravelling the geological processes that transform an ordinary slice of the earth's crust into a world class copper deposit, a resource in demand for the green energy revolution. Working with rocks, I investigated how the composition of minerals within them could unveil a rich tapestry of geological history. Among these minerals, apatite, a phosphate mineral, emerged as a key player, offering a detailed, time-resolved archive of magmatic to hydrothermal processes crucial for understanding the formation of copper resources.

However, tapping into the chemical insights locked within apatite crystals proved to be a formidable challenge. These elusive crystals, often no larger than the width of a human hair, and comprising less than 1% of most rock samples, posed a daunting task for detailed analysis. Imagine trying to spot these minuscule crystals within samples larger than 3 cm2 ̶ the geological equivalent of finding a needle in a haystack!

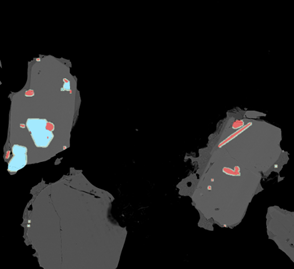

To address this challenge, I employed a scanning electron microscopy (SEM) technique involving high-resolution automated mapping utilising separate X-ray and backscattered electron (BSE) detectors. This method entailed capturing BSE images and leveraging grayscale filters to facilitate targeted energy dispersive X-ray spectroscopy (EDX) analysis of bright phases within the image (such as dense apatite, which appears bright in BSE images), thereby confirming the presence and precise location of apatite crystals within a large sample (figure 1). This was a great help; such analyses could be fully automated and individual fields were montaged together, effectively producing a large area map of apatite crystals! Subsequently, more focused, and extensive analyses of apatite could be carried out based on these comprehensive area maps.

However, there were drawbacks to this approach. An automated run could consume anywhere from 3 to 5 hours per sample, and it needed to be conducted across a sizable sample suite. Applying greyscale filters also means that much of the sample goes unanalysed, potentially missing important contextual information. Considering that automated runs incurred charges on an hourly basis, this inevitably led to significant analytical costs throughout the duration of my PhD.

The Potential of BEX

Conversely, the Unity BEX detector boasts high-count rates (10-100 times that of standard EDS detectors) and facilitates simultaneous acquisition of EDS and BSE data. This breakthrough significantly accelerates the pace of combined image and compositional data acquisition. Using Unity, generating the large area maps I required would likely take only a fraction of the time compared to using traditional methods. Moreover, there's no need to apply grayscale filters to isolate chemical analyses of bright phases; instead, I could simply let the detector raster across the sample surface, producing a comprehensive chemical map (figure 2). This approach would produce a wealth of chemical insights across the entire sample, enabling me to also identify the composition of the larger and more abundant mineral phases within the rock. Such contextual information often proves vital in supporting the interpretation of data derived from accessory minerals like apatite.

Moreover, following the generation of large area maps, the AZtec software offers a user-friendly and intuitive function; the ability to precisely navigate the stage to specific crystals of interest by clicking on the large area image. Given the distinctive calcium and phosphorous-rich composition of apatite, identification becomes straightforward using these element maps with false colour (figure 2). This functionality enables precise manipulation of apatite crystals into focus, facilitating rapid subsequent point analyses.

By swiftly adjusting the acquisition settings, I could then conduct the necessary point analyses to enhance the quality of minor element data quantification. Thus, beginning the process of unravelling the geological history encapsulated within this mineral and discussing the importance of that history for generating copper deposits.

Now, as I embark on my new role as a product scientist within the Oxford Instruments NanoAnalysis team, I eagerly anticipate the opportunity to leverage the BEX technique through the Unity detector. It is my hope that fellow researchers using automated mineralogy can glean insights and advantage from this blog post, ultimately streamlining analytical workflows and reducing the associated facility costs.