5th May 2021 | Author: Hui Jiang

The technical cleanliness of components is crucial to their performance in finished products. As such, the assessment of the level of cleanliness of components is applicable in a wide range of industries; any involving the manufacture of mechanical devices such as the automotive industry. A typical example of such a component is ball bearings which are at the heart of almost every product with a rotating shaft.

The manufacture of bearings is a very precise process with, in some cases, very low tolerances being required. It is entirely possible for a particle of 5 microns or less to cause a precision bearing to fail; very small particles have the potential to cause major damage. Even if such particles are not the immediate cause of failure, they can decrease a bearing’s smooth-running qualities and low torque values and impact on its lifetime. Therefore, it is important that a high degree of cleanliness is maintained during the manufacture of precision bearings. An assessment of cleanliness, as part of quality control, is crucial to ensuring consistent bearing performance. Residual particles may originate from the manufacturing or assembly processes or be introduced from the environment. In order to know if particle levels are within acceptable limits and in order to attempt to identify the source of particles, it is important to know both their composition and morphology so that the manufacturing processes can be monitored and optimised.

A solution to this problem is to use an SEM based approach utilising automated particle analysis with AZtecClean which is optimised to perform technical cleanliness analysis to international standards such as ISO 16232 and VDA19. By utilising large area EDS detectors, a high throughput can be achieved with a full particle by particle compositional and morphological characterisation made. This allows for the calculation of comprehensive summary statistics for the sample in accordance with international technical cleanliness standards. Here, we show an example of the use of AZtecClean to report on the cleanliness of a deep groove ball bearing manufacturing process to these standards.

To carry out a cleanliness analysis, a sample was prepared by washing a known volume of finished product. These particles were captured on a membrane filter, which was then attached to a sample stub and coated with carbon to minimise charging of the non-conductive filter material under the electron beam of the SEM.

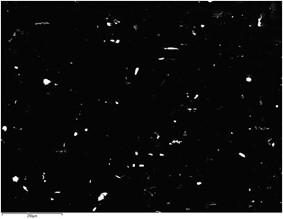

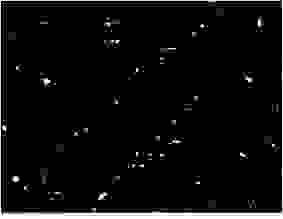

The sample was imaged using the SEM’s backscattered electron (BSE) detector. Contrast in BSE images is generated by the density of the phase, making BSE imaging ideal for determining particle locations. As the majority of particles are made of dense elements, they appear brighter than the background filter material in a BSE image as shown in Fig. 1.

Fig. 1 BSE image showing particles on a filter

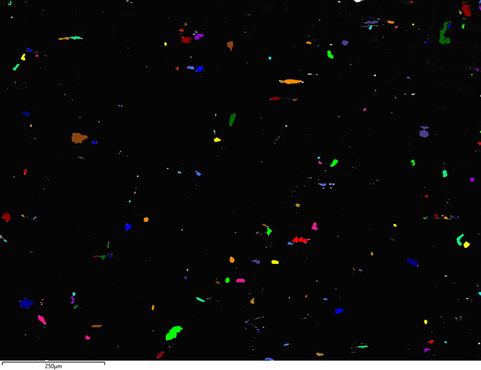

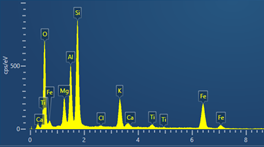

The particles were identified and separated from the dark background by means of a single grey threshold. This information was then used to determine where EDS measurements should be taken. The morphology of all particles falling in this threshold was measured automatically and instantly was combined with compositional data from the subsequent EDS analysis. Fig. 2 shows an example of a field of view where a number of particles have been detected.

Fig. 2 (Left) Particles meeting detection criteria are detected and coloured. (Right) Typical spectrum acquired from a silicate particle at 20kV

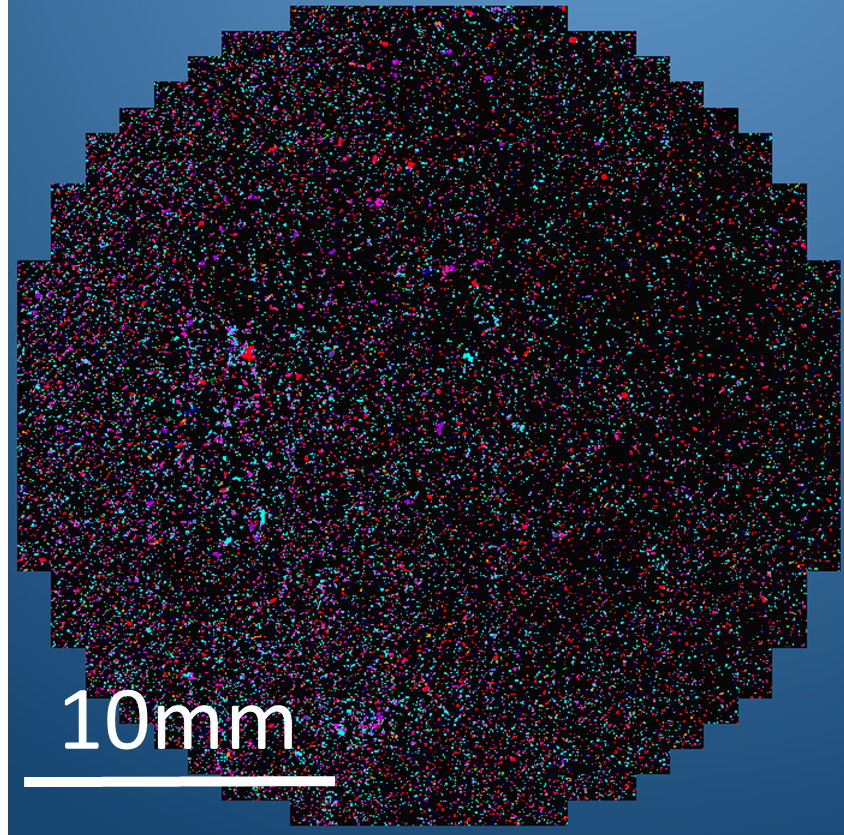

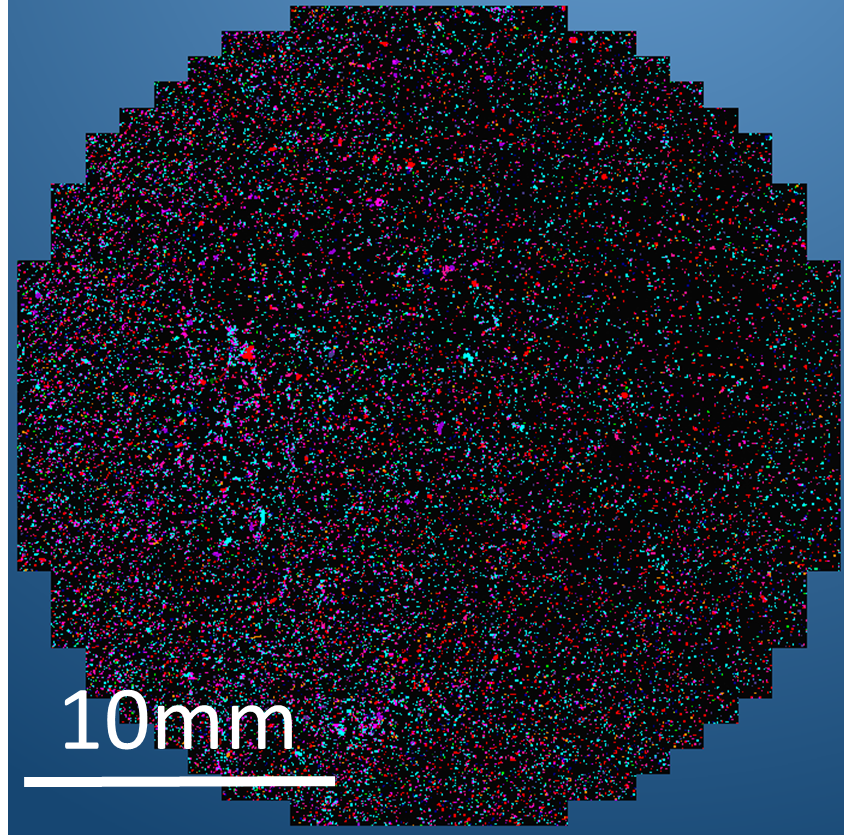

Fig. 3 Montaged Image of the Entire Filter Showing Detected Particles

Normally the entirety of a filter will be analysed automatically to ensure every particle is found. Fig. 3 shows a montaged image from a total circle area in excess of 506mm2. 31249 particles were detected, analysed, and classified in real time. Particles are coloured by their classification as shown in Fig.4.

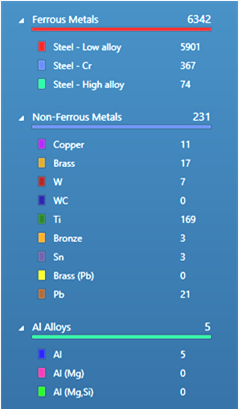

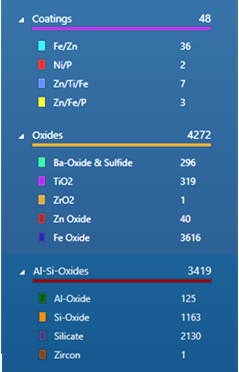

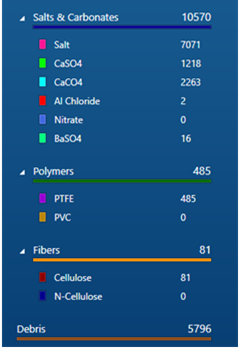

Fig. 4 classification totals and colour key for entire filter analysis run

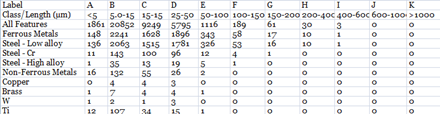

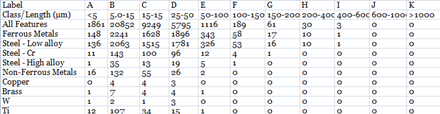

The ‘component cleanliness reporting sheet’ required to meet the ISO16232 and VDA19 standards is generated automatically (Table. 1).

Table 1: Subset of Technical Cleanliness Results for this sample reported to the size bins defined by ISO16232 and VDA 19.

Component cleanliness code (CCC) per wetted volume or area is also calculated from this data. The CCC for this example is:

CCC=V (B15/C14/D13/E11/F8/G6/H5/I2/JK00)

The use of a dedicated classification scheme and reporting with pre-optimised settings ensures that data is consistently and reliably acquired in accordance with these standards.

Hopefully this gives you an idea how technical cleanliness analysis is performed with AZtecClean. To develop a more thorough understanding of how we can help you to improve the technical cleanliness of ball bearings please download our application note here.