Elemental and Structural Characterisation of Device Failures

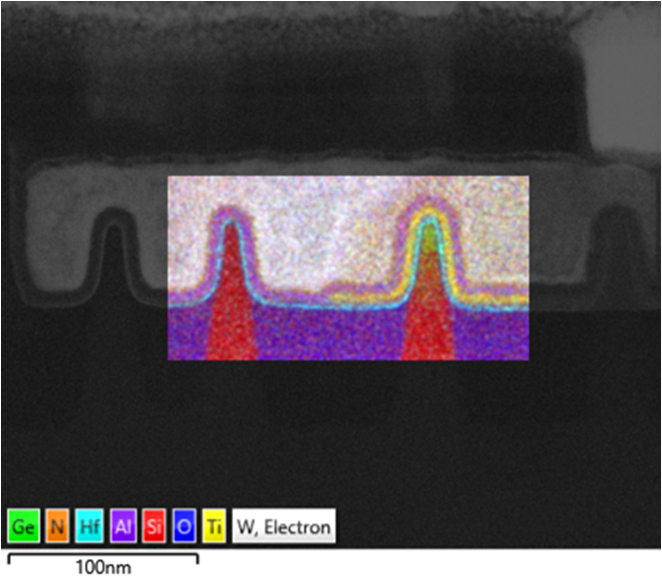

Once a failed device has been found and isolated from the rest of the die, the true detective work begins to identify the root cause of that failure. The cause of that failure could be due to inconsistency in the chemistry of the process, foreign contaminant particles or variation in crystalline structure of deposited material amongst many other possibilities. Many of these potential fault causes are extremely small, typically on the order of a few nanometres. Our latest generation Ultim Extreme energy dispersive x-ray spectrometer (EDS) allows you to work at the same conditions that you would image in the SEM to get elemental information at 10 nm resolution on bulk devices.

In the TEM our Ultim Max TEM detectors are powered by AZtecTEM to ensure the higher possible accuracy quantitative analysis at the highest possible resolution.

Application Note: Mapping Semiconductor Devices in the SEM

Download the application note

Application Note: Semiconductor mapping in the TEM

Download the application note

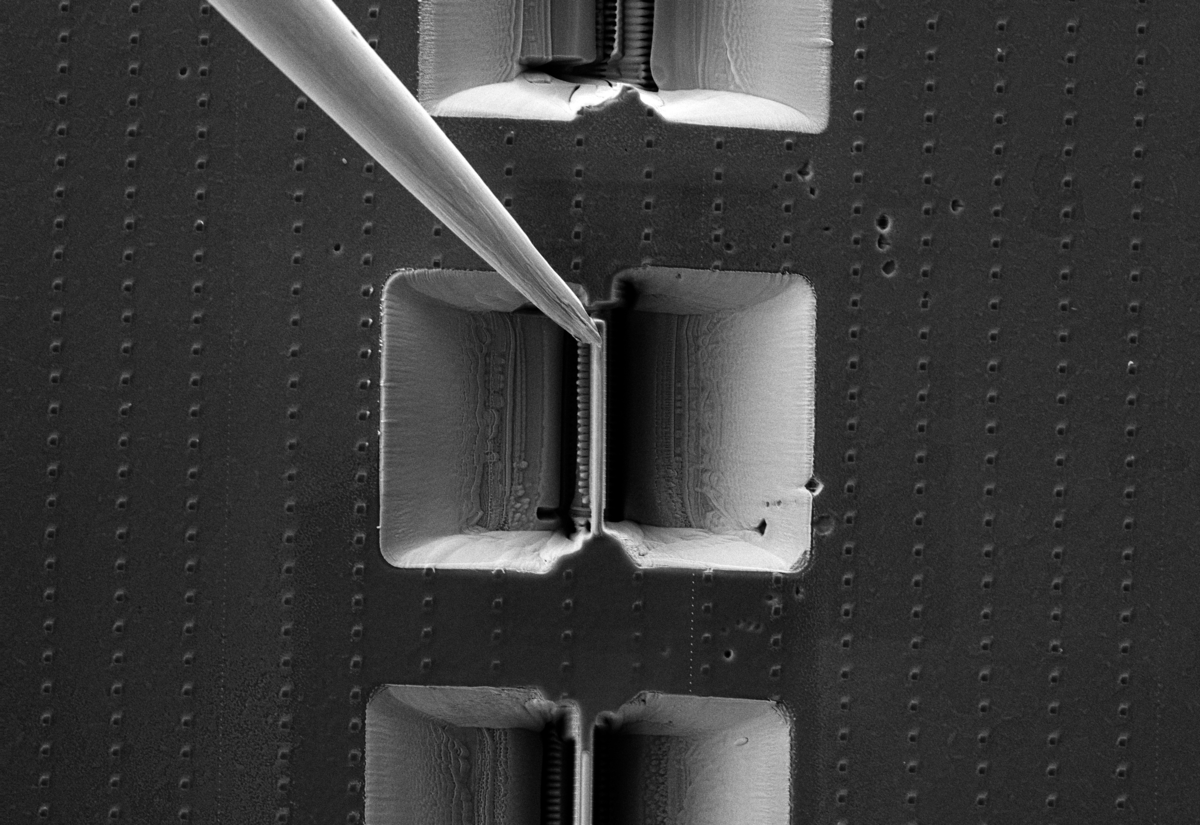

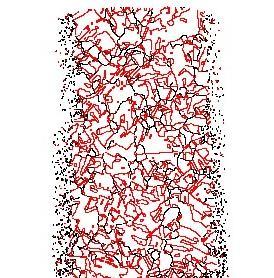

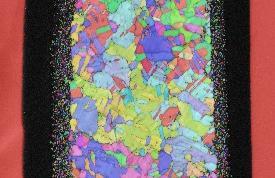

Not all device failures are chemical in nature. Some are due to the structure or even phase of deposited material. Electron backscatter diffraction (EBSD) collects an electron diffraction pattern at every pixel of an SEM image allowing characterisation of local crystal structure. By processing these diffraction patterns the grain structure, relative orientations, grain boundary orientations and even local stress and strain can be analysed. This allows correlation of device properties with the structure which can be particularly useful for understanding the conductivity of metailsed interconnects and through silicon vias. Combined with EDS the phase of a material can be determined not just its structure or elemental composition. Symmetry EBSD is the first CMOS based detector delivering higher speed and sensitivity than any other EBSD camera. This enables the user to collect higher quality data in a shorter time maximising productivity.

Get in touch