2 Apr

New Application Note from Asylum Research: “AFM Investigation into Tribofilm Formation”

Friction between the surfaces of mechanical systems is a costly global problem. It is not just that the resulting wear leads to premature equipment failures. Friction is also one of the leading factors that reduce energy efficiency, thought to account for more than 20% of worldwide energy consumption. Scientists and engineers in the field of tribology look for ways to reduce friction in order to reduce these economic and environmental costs. Atomic Force Microscopy (AFM) is powerful tool for investigating what happens at the nanoscale between these sliding interfaces.

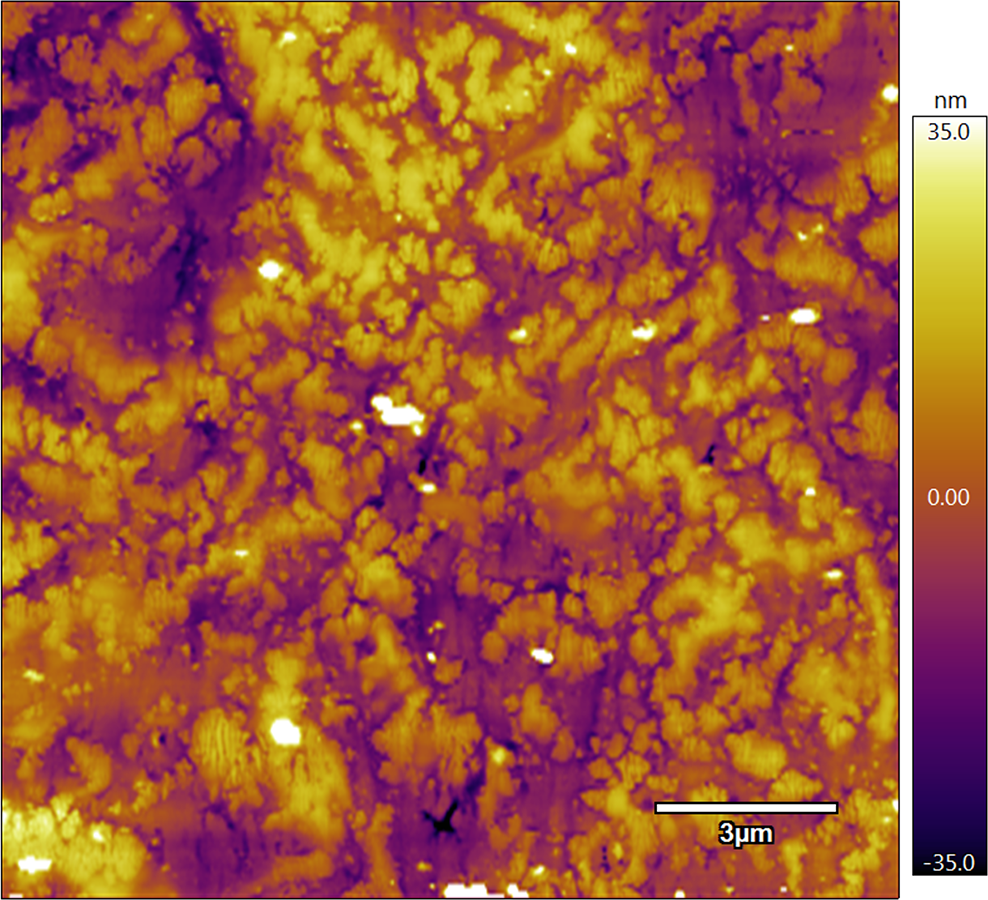

Image caption: Topography of a tribofilm formed after only six hours of wear on a macroscale sliding ball tribometer. The scan area shown here is 15 µm, but Asylum Research AFMs can inspect such interfaces at scales ranging from a few nanometers to over 100 µm. The Jupiter XR large-sample AFM can accommodate samples up to 210 mm in diameter, enabling measurements on actual components.

The new application note examines how Asylum Research AFMs can characterize the so-called “tribofilms” that form at these interfaces. The films form over time as the material reacts with air, water, lubricants, and other compounds in the environment. These tribofilms can dramatically alter the frictional characteristics of the contact. The high-resolution imaging capabilities of Asylum AFMs allow the three-dimensional morphology of tribofilms to be imaged with nanometer-scale resolution. Examples in the paper show, however, how AFM can go far beyond simple topographic imaging. The AFM tip can be used as a tribometer, enabling reciprocating sliding wear experiments to be conducted at the nanoscale. This enables the measurement of frictional forces that vary across different regions and components of the tribofilm. Asylum Research AFMs also offer a unique set of nanomechanical characterization techniques that can measure the modulus and dissipative properties of the tribofilm. This information can help scientists and engineers understand how the tribofilms affect friction and potentially inform new strategies to reduce wear and energy losses.

For more information see https://afm.oxinst.com/tribofilm

DOWNLOAD THE APP NOTE

DOWNLOAD THE APP NOTE