Resources

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

The most flexible confocal imaging systems available; from routine imaging to the most advanced techniques. Our game-changing Dragonfly systems are rich in innovative technology to provide fast and high-resolution imaging in multiple imaging modalities. Our new BC43 benchtop confocal microscope brings high-end confocal imaging within a compact benchtop format.

Request Pricing Product Selection ToolAndor's new BC43 Benchtop Confocal is a push-button imaging solution designed with cost, performance and accessibility in mind. Make stunning 2D and 3D images part of your routine benchtop workflow.

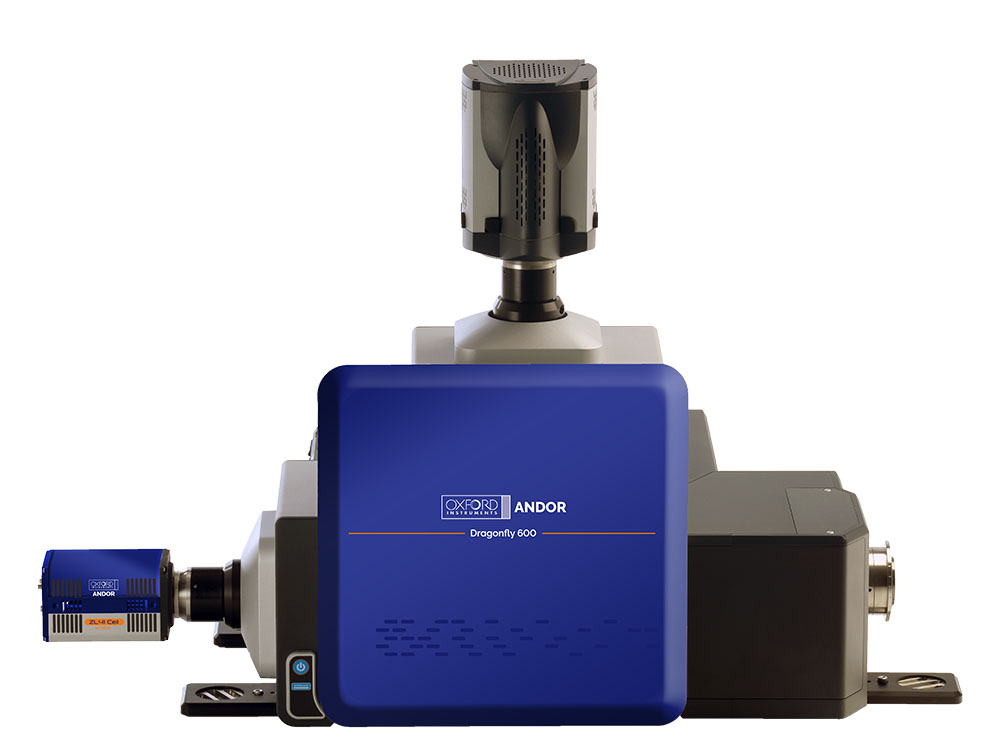

Dragonfly high-speed confocal microscopy systems provides a combination of speed, sensitivity, confocality and resolution. Our multi-modal imaging solutions improves your understanding of dynamic events in living samples, and boosts your productivity when imaging large specimens and tissue samples.

Try our confocal system selector tool to select and compare products by application or technology. If you want to discuss the specific needs of your imaging experiments, you can contact one of our Andor Specialists.

Push-button confocal microscope. A routine workhorse – high-performance and easy to learn.

Compact for use on a regular laboratory bench.

A flexible, multi-modal platform that offers confocal, laser based widefield, transmitted light and SRRF-Stream+ functionality in one system.

A complete system that builds on the capabilities of the 200 model to also include SMLM, 3D super-resolution module, B-TIRF and Zoom Illumination.